Let's be honest: when you hear "supply chain modeling," it might sound overly technical or complex. But the core idea is surprisingly simple. Think of it as creating a digital blueprint of your entire logistics network.

This isn't just a static map. It's a living, breathing model you can use to test out different scenarios, predict where bottlenecks might pop up, and ultimately find the absolute best path for your products to take from A to Z.

What Is Supply Chain Modeling?

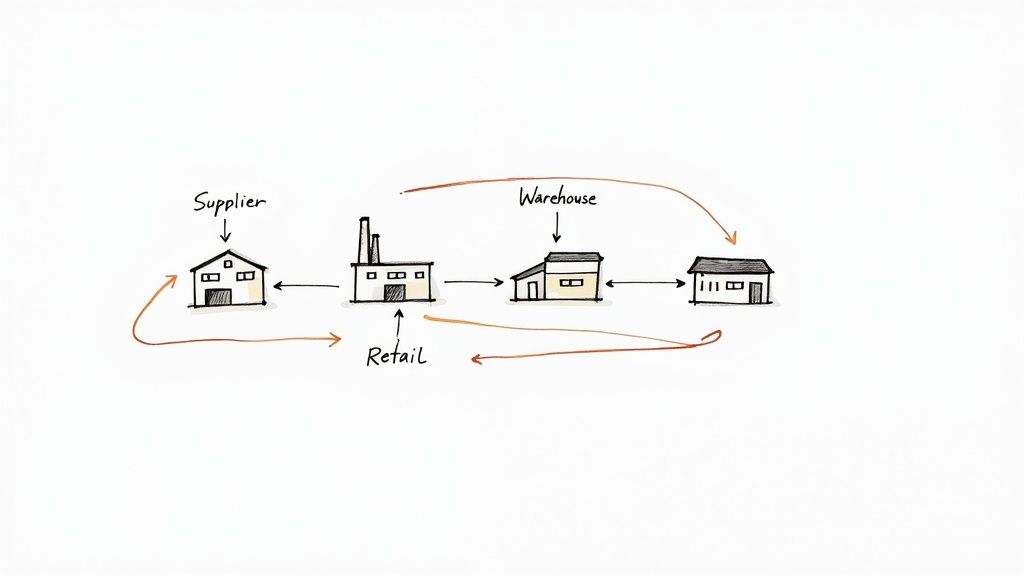

At its heart, supply chain modeling is the practice of using data and smart algorithms to build a virtual replica of your entire operation. This "digital twin" covers every single touchpoint—from the suppliers of your raw materials, through your manufacturing plants, to your warehouses and distribution centers, and all the way to your customer's doorstep.

It's much more than a pretty diagram; it's a powerful, interactive sandbox for your business.

Once you have this model, you can stop just reacting to problems and start asking proactive, game-changing "what-if" questions. What happens to our delivery promises if a major port shuts down? How would opening a new warehouse in Texas impact our costs versus our customer service in the Southwest? Which shipping routes give us the best mix of speed and savings?

Why Modeling Is Now a Necessity, Not a Luxury

Not too long ago, many businesses got by with simpler, more traditional planning methods. Spreadsheets and experience were often enough. But today's business world is defined by constant change and gut-wrenching unpredictability.

Just look at the recent data. Global disruptions, from the COVID-19 pandemic to geopolitical conflicts, have thrown a wrench into supply chains everywhere, causing massive slowdowns and cost spikes. As a result, companies are scrambling for better visibility and adopting new tech to stay afloat. If you want to dig deeper, the latest supply chain statistics from Fictiv paint a very clear picture.

This is exactly where supply chain modeling steps in, providing the clarity you need to navigate this chaos.

A well-built model is like a flight simulator for your supply chain. It lets you test your network's strength against any potential disruption in a completely risk-free environment. You can crash-test your plans and build a proven contingency strategy before a real crisis ever hits.

The Core Problems It Solves

Effective supply chain modeling isn't just an academic exercise; it directly tackles some of the most stubborn and costly challenges that businesses face every day. It provides a structured method for turning a mountain of operational data into clear, actionable strategies.

Below is a quick look at the major business headaches that modeling helps cure.

Core Problems Solved by Supply Chain Modeling

| Problem Area | How Modeling Provides a Solution | Business Value Delivered |

|---|---|---|

| High Operating Costs | Pinpoints the best locations for facilities, ideal inventory levels, and most efficient transport routes to slash expenses. | Significant cost reduction in logistics, warehousing, and transportation. |

| Poor Customer Service | Simulates different inventory strategies and delivery networks to find the fastest, most reliable way to serve customers. | Improved on-time delivery rates and higher customer satisfaction scores. |

| Vulnerability to Disruptions | Runs "what-if" scenarios for events like supplier outages or port closures to build robust contingency plans. | Increased operational resilience and a lower risk of expensive downtime. |

| Inefficient Resource Use | Determines the perfect amount of production capacity, warehouse space, and transportation needed to meet actual demand. | Better asset utilization and avoidance of unnecessary capital spending. |

Ultimately, a good model moves your decision-making process from being based on guesswork and gut feelings to being a data-driven science. In today's market, that’s not just an advantage—it's a necessity.

Of course. Here is the rewritten section, crafted to sound like an experienced human expert and match the provided writing style.

The Evolution of Supply Chain Planning

The sophisticated supply chain modeling we depend on today didn't just pop into existence. Its backstory is a fascinating ride that mirrors the evolution of technology itself, starting with paper ledgers and clunky calculators and ending with the predictive digital engines that now power global commerce. It's a story of how simple record-keeping morphed into a powerful strategic weapon.

The first seeds were sown back in the 1960s. This decade brought fundamental changes to how things moved, as trucking began to dominate freight transport. This shift was supercharged by deceptively simple innovations like pallets and standardized shipping containers, which made hauling materials and products across vast distances dramatically more reliable and efficient.

This physical evolution quickly sparked a digital one. In the mid-1960s, we saw the first real attempts at computerized inventory management. IBM was at the forefront, developing the first system in 1967 that started replacing slow, error-filled paper records with the speed and precision of digital data. You can dive deeper into this game-changing era in this history of the global supply chain from Blume Global.

The Dawn of Digital Management

Interestingly, the term “Supply Chain Management” wasn't even coined until 1983. The timing makes perfect sense—it emerged right alongside the personal computer, the device that put real data analysis into the hands of businesses everywhere. All of a sudden, managers could tinker with spreadsheets and basic mapping software to track costs and optimize delivery routes, right from their own desks.

This was a massive leap from the mainframe-dependent systems of the prior decade. It put foundational modeling tools into the hands of a much wider group of people, allowing companies to do more than just count inventory. They could start asking strategic questions about their operations. The focus began to shift from just, "What do we have?" to, "What's the smartest way to manage it?"

For the first time, businesses could actually visualize their networks and play with different scenarios without needing a team of specialized programmers. This newfound accessibility ignited a completely new way of thinking about logistics as one interconnected system, not just a bunch of separate tasks.

The ERP and Globalization Game-Changers

The 1990s unleashed another monumental shift with the rise of Enterprise Resource Planning (ERP) systems. These platforms knitted together all the different parts of a business—from purchasing and manufacturing to finance and shipping—into a single, unified database. This created a single, cohesive view of the entire supply chain from end to end.

ERP systems effectively demolished the data silos that had always held businesses back. By creating a single source of truth, they laid the groundwork for the more advanced and comprehensive supply chain modeling we see today.

This tech breakthrough happened to coincide with another massive force: globalization. As companies started sourcing parts from one continent and selling finished goods on another, their supply chains exploded in complexity. Trying to manage a network spanning multiple countries, time zones, and regulations with just a spreadsheet was simply impossible.

This combination of integrated ERP data and the intense pressure of a global market turned advanced supply chain modeling from a nice-to-have into an absolute necessity. It became the essential tool for taming complexity, heading off new risks, and squeezing out efficiencies on a global scale. This pressure is what forced the discipline to mature so quickly, paving the way for the sophisticated optimization and simulation tools we rely on today.

Choosing Your Supply Chain Modeling Method

Once you see the power of building a digital blueprint for your operations, the next question is obvious: which tool do you use? Not all supply chain modeling techniques are the same. Each is built to answer different business questions, and picking the right one is like a craftsman choosing the perfect tool—you wouldn't use a sledgehammer when you need a scalpel.

This is where we get into the core techniques behind modern modeling. We’ll explore three primary methods that form the foundation of strategic supply chain analysis: Optimization, Simulation, and Heuristics. Getting a handle on what each one does is the secret to pulling real, actionable insights from your data.

Optimization: The Search for the Best Answer

Think of optimization modeling as a hyper-intelligent GPS for your entire supply chain. You tell it your destination—for example, the lowest possible total cost—and feed it all your rules and constraints, like production capacity, warehouse space, and customer delivery windows. The model then crunches every possible scenario to find the single most efficient path to get there.

This method uses powerful mathematical algorithms to pinpoint the ideal solution from a sea of possibilities. It’s perfect for answering big, definitive questions with a clear, measurable goal.

- Network Design: What is the absolute best number and location for our distribution centers to hit a 98% on-time delivery target at the lowest cost?

- Production Planning: Which factories should make which products to meet global demand with the smallest manufacturing and transport spend?

- Inventory Policy: What is the perfect amount of safety stock to keep at each location to prevent stockouts without tying up too much cash?

The main job of optimization is to find the "best" answer according to the rules you give it. It’s a game-changer for making major strategic decisions where millions of dollars are at stake. But its greatest strength is also its weakness: it assumes a predictable world and can struggle to account for random, disruptive events.

Simulation: Stress-Testing for an Uncertain World

If optimization is your GPS, then simulation modeling is your flight simulator. Its purpose isn't to find a single "best" answer. Instead, it lets you run thousands of "what-if" scenarios to see how your supply chain would hold up under different conditions—especially stress and disruption.

This approach is priceless for building resilience and preparing for the unexpected. It’s your chance to pressure-test your entire network in a completely risk-free, digital world.

With simulation, you can throw any imaginable challenge at your supply chain—a sudden demand spike, a key supplier going bankrupt, a major shipping lane closing—and see exactly where the breaking points are. This proactive insight is critical for building robust contingency plans.

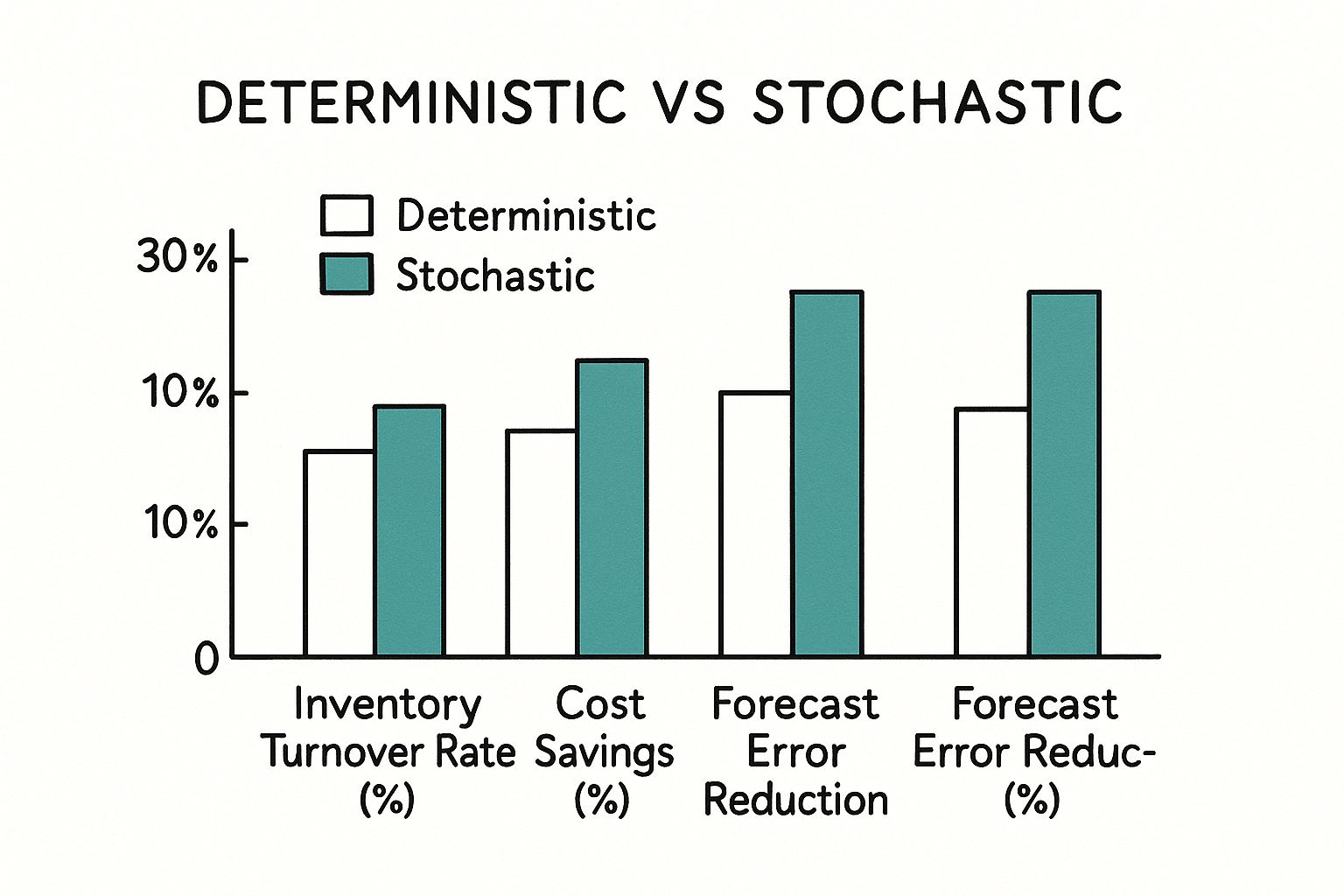

Instead of assuming everything will go as planned, simulation embraces variability. It often uses stochastic modeling, which bakes in randomness and probability to mirror real-world volatility. You can model swings in customer demand, supplier lead times, and transport delays to get a much more realistic view of your operational performance.

The chart below shows the performance jump businesses often see when they move from a simple deterministic model (which assumes predictability) to a more realistic stochastic one that accounts for real-world chaos.

As you can see, models that embrace uncertainty consistently drive better results, from higher inventory turnover to bigger cost savings.

Heuristics: Smart Shortcuts for Fast Decisions

Finally, we have heuristics. Think of these as intelligent "rules of thumb" or educated shortcuts. They're used to find a good, workable solution quickly, especially when a problem is too massive or complex for a perfect optimization model to solve in a reasonable amount of time. They don't promise the absolute best mathematical answer, but they deliver a highly effective one in a fraction of the time.

It’s like planning a cross-country road trip. Optimization would calculate every single possible route down to the second to find the one that's five minutes shorter. A heuristic approach would simply stick to major highways, knowing it’s a reliable and efficient strategy that gets you there 99% as fast with far less number-crunching.

Heuristics are fantastic for:

- Vehicle Routing: Quickly generating efficient daily delivery routes for a fleet of trucks.

- Warehouse Slotting: Assigning products to storage locations based on simple rules like, "place the fastest-moving items closest to the shipping docks."

These methods are pragmatic, fast, and incredibly useful for the tactical, day-to-day decisions where speed matters more than theoretical perfection. They're an essential part of the supply chain modeling toolkit for keeping your operations running smoothly.

Comparing Supply Chain Modeling Methodologies

To make it even clearer, let's break down these three powerful approaches side-by-side. Each has its place, and understanding their core purpose will help you match the right method to the right business problem.

| Methodology | Core Purpose | Best For | Key Limitation |

|---|---|---|---|

| Optimization | To find the single, mathematically best solution. | Major strategic decisions like network design and long-term production planning. | Assumes a predictable world; struggles with randomness. |

| Simulation | To test performance under many "what-if" scenarios. | Risk analysis, contingency planning, and building operational resilience. | Doesn't provide a single "best" answer, only outcomes. |

| Heuristics | To find a good, workable solution quickly. | Tactical, day-to-day decisions like vehicle routing and warehouse slotting. | Provides a "good enough" answer, not the perfect one. |

As you can see, the choice isn't about which method is superior overall, but which one is perfectly suited to the question you need to answer right now. A well-rounded supply chain strategy often involves using all three at different times.

How to Build Your First Supply Chain Model

Jumping into supply chain modeling can feel overwhelming, but it’s really just a matter of following a clear, structured process. Don't think of it as some impossible feat. It’s more like building with LEGOs—you start with a simple foundation and add pieces one by one until a complex structure emerges.

This guide will walk you through building your first model, step-by-step. We'll turn abstract concepts into a practical tool you can use to make real improvements to your business. The whole thing boils down to five stages: define, gather, build, analyze, and implement.

Step 1: Define Your Objective

Before you even think about data, you have to answer the most important question: What problem are you trying to solve? A model without a clear goal is just a science project. It won't deliver any value.

Vague goals like "improving efficiency" are useless. You need to be specific and measurable. Think in terms of tangible business outcomes.

For example, instead of "make things better," try:

- "Cut transportation costs between our West Coast warehouse and top 10 retail partners by 15%."

- "Find the ideal inventory levels for our top 20 SKUs to hit a 98% service level without overstocking."

- "Figure out if a new distribution center in the Midwest will drop our average delivery time by 24 hours."

A crystal-clear objective is your north star. It guides every decision you make, from the data you collect to the methods you use.

Step 2: Gather and Clean Your Data

With your objective set, it's time to hunt for data. Fair warning: this is usually the most time-consuming part of the process, but it's also the most critical. There's an old saying that's gospel in modeling: "garbage in, garbage out." Your model's insights can never be better than the data you feed it.

Start by listing the data points you absolutely need. For that transportation cost model we mentioned, you'd be looking for:

- Shipment records: Where things are coming from, where they're going, volumes, weights, and how often.

- Carrier rates: The actual cost per mile or per shipment for your different transport options.

- Lead times: How long it takes for shipments to travel along key routes.

- Facility details: Where your warehouses are located and their operating hours.

Once you have the data, you need to clean it up. This means fixing typos, filling in missing values, and making sure everything is in a consistent format. It's tedious work, but spending time here ensures your model actually reflects reality.

Step 3: Build and Validate the Model

Okay, now for the fun part: building the model itself. Based on your objective, you'll pick the right methodology. Are you trying to find the best possible solution? That's optimization. Want to test a bunch of "what-if" scenarios? That's simulation.

Building the model means translating your physical network—your warehouses, routes, and rules—into a logical structure inside your chosen software. You'll define facilities as nodes, shipping lanes as links, and add real-world constraints like truck capacity or customer delivery windows.

A model is just a hypothesis until it's validated. This is where you test your model against historical data to make sure it actually behaves like your real-world supply chain. If the model can't accurately replicate what happened in the past, you can't trust it to predict the future.

This means running the model with old data and checking if its outputs (like total costs) match what really happened. You'll likely need to go back and tweak your assumptions until the model's results line up with reality.

Step 4: Analyze Scenarios and Implement Insights

Once your model is validated, the real work begins. This is where you get to play and ask all your "what-if" questions. What happens if we switch carriers? What if we add a new supplier? What if we reroute deliveries around a congested area?

Run different scenarios and analyze the results. Your analysis might show that by consolidating shipments and using a different regional carrier, you could actually cut costs by 18%—beating your original goal.

But remember, insights are worthless if they just sit in a PowerPoint slide. The final step is to create a clear action plan to put your findings into practice. Monitor the results, see what works, and keep refining. This turns your supply chain modeling from a one-time project into a powerful engine for continuous improvement.

How AI and Digital Twins Transform Modeling

Traditional modeling methods are great for giving you a snapshot of your supply chain—a clear picture of a single moment in time. But what if you could have a living, breathing video feed instead? That’s the new reality being built with Artificial Intelligence (AI) and digital twins, a combination that's completely rewriting the rules of supply chain management.

This isn’t just a minor upgrade. It’s a fundamental leap from looking in the rearview mirror (what happened and why) to looking through the windshield and using a GPS (what will happen and what should we do about it?).

Enter the Digital Twin: A Living Replica

At the heart of this change is the digital twin. Imagine an exact virtual copy of your entire supply chain. Every supplier, factory, warehouse, and shipping lane is mapped out and constantly fed real-time data from IoT sensors, GPS trackers, and your own operational systems.

This isn't a static model you dust off once a quarter. It's a dynamic, always-on mirror of your physical operations. It gives you a level of visibility that was once unthinkable, letting you see exactly how your entire network is performing, right now.

The real magic of a digital twin is its ability to act as a high-fidelity sandbox. You can test-drive a new warehouse location or simulate a port shutdown on the virtual model without risking a single dollar in your actual operations. It’s about gaining priceless foresight before you commit.

How AI Elevates Modeling

If the digital twin is the perfect testing ground, AI is the brilliant strategist running the simulations. Artificial intelligence and its powerhouse subfield, machine learning (ML), sift through the endless streams of data flowing into the twin, finding hidden patterns, automating decisions, and making predictions with startling accuracy.

Here’s how AI gives your modeling superpowers:

- Pattern Recognition: AI algorithms can spot faint signals in massive datasets that are completely invisible to human analysts. It might notice that a tiny delay at one specific port consistently leads to a stockout three weeks down the line, a connection no one had ever made.

- Predictive Power: By learning from history and watching real-time events unfold, AI can forecast disruptions before they happen. It might flag a potential production slowdown by detecting unusual sensor readings from a machine in your key supplier’s factory.

- Automated Decision-Making: This is where it gets really interesting. AI can move beyond just telling you what to do and actually start doing it. For example, it could automatically reroute a shipment that’s already in transit to avoid a sudden highway closure, choosing the next best route in seconds.

Building the Self-Healing Supply Chain

The ultimate goal of combining AI and digital twins is to create a self-healing supply chain. This is a network so intelligent that it can not only anticipate problems but also automatically react and adapt to solve them, often without any human intervention at all.

Think of it playing out like this:

- Anticipate: An ML model predicts a key supplier will miss a delivery deadline by 48 hours because of an incoming storm system.

- Analyze: The digital twin instantly runs a simulation, showing that this delay will cause a critical component to run out, shutting down a production line.

- Act: The AI system immediately evaluates the best workarounds. It determines that expediting a smaller order from a secondary supplier is the most cost-effective way to prevent the shutdown.

- Execute: The system places the new order and adjusts the production schedule on the fly, completely neutralizing the disruption before it ever hits the bottom line.

This closed-loop system of sensing, analyzing, and acting is the future of operational resilience. Companies that get this right are building supply chains that aren't just strong, but smart and agile enough to thrive in a world that’s anything but predictable.

Supply Chain Modeling Success Stories

Theory is one thing, but the real power of supply chain modeling snaps into focus when you see its impact in the real world. These aren't just academic exercises. They're strategic moves that save companies millions, shield them from chaos, and carve out a serious competitive advantage.

Let's look at how different businesses have put modeling to work and achieved some pretty remarkable results.

One of the most common wins is in network design. A major big-box retailer was wrestling with runaway logistics costs and delivery times that were all over the map. By creating a digital twin of their entire distribution network, they could run scenarios to pinpoint the perfect spots for new distribution centers.

The model identified two ideal locations that would dramatically shorten delivery routes and better balance their inventory loads. The payoff? They sliced over $15 million from their annual logistics budget and boosted their on-time delivery rate by an incredible 22%. It's a textbook example of the massive ROI that smart modeling can deliver.

Building Resilience Against Disruption

In today's volatile world, you have to be ready for anything. A global consumer packaged goods (CPG) company was worried about how much they relied on a handful of key international ports. They knew that a single major closure—whether from a labor strike or a natural disaster—could paralyze their ability to get products to market.

So, they used simulation modeling to stress-test their entire network. By running thousands of "what-if" scenarios, they found their biggest weak points and built a solid contingency plan. This blueprint included pre-vetted alternative ports and dynamic rules for reallocating inventory on the fly.

A year later, it happened. A major port shut down unexpectedly for two weeks. While their competitors scrambled and bled sales, the CPG giant was ready. They seamlessly rerouted shipments according to their model, protecting revenue and cementing their reputation for being reliable.

This is the strategic edge of proactive supply chain modeling—it turns potential disasters into manageable operational pivots.

Supercharging Modern Inventory Strategies

Smart inventory management has been a business fundamental for decades. Back in the '80s and '90s, the rise of Enterprise Resource Planning (ERP) systems and strategies like Just-In-Time (JIT) inventory, pioneered by Toyota, changed the game by slashing waste and storage costs. You can get a great overview of how technology shaped this evolution from Opsdesign.com.

Modern modeling takes these proven ideas to a whole new level. A leading tech company, for instance, wanted to use a JIT strategy for its expensive components but was dealing with wildly unpredictable consumer demand. A simple JIT approach was just too risky; they could easily run out of stock.

Instead, they built a sophisticated model that blended demand forecasting with inventory optimization. It calculated the exact reorder points and safety stock levels needed to absorb demand swings while keeping inventory costs razor-thin. By powering up a classic strategy with modern data analysis, they cut their inventory holding costs by 30% while meeting nearly 100% of customer orders, even during surprise demand spikes.

Got Questions About Supply Chain Modeling? We've Got Answers.

Jumping into supply chain modeling can feel like a huge leap. It’s natural to have questions, whether you're mapping out your very first project or just looking to sharpen your current methods. Let's clear up some of the most common questions and show you the real-world value hiding in your data.

How Much Data Do I Really Need to Get Started?

This is the number one question we hear. There's a common myth that you need a flawless, gigantic dataset before you can even think about modeling. The truth? You can start small and build from there.

The smart way to begin is by picking one specific, nagging problem. Think about optimizing costs for a single shipping route or figuring out the right inventory levels for your top 5 products.

For a focused project like that, you just need the basics:

- Historical shipping costs and delivery times.

- Your current inventory numbers and warehouse locations.

- Past sales data for the products you're looking at.

The game plan is simple: start with the data you already have. Prove the concept on a small scale, get a quick win, and then use those results to get buy-in for bigger, more ambitious projects.

Is This Just for Giant Corporations?

Not at all. While the big global players absolutely depend on massive, complex models to run their operations, the core ideas deliver value for businesses of any size. In fact, small and medium-sized businesses often see the most dramatic improvements from even simple modeling.

A few years ago, this kind of power was locked away in expensive, enterprise-only software. Today, modern cloud-based tools have completely leveled the playing field, giving smaller companies the same optimization and simulation muscle as the big guys.

It's not about the size of your company; it's about matching the model's complexity to your business needs. For a smaller business, a simple model can be the key to unlocking major shipping savings, freeing up cash tied up in inventory, and delivering the kind of service that lets you compete with anyone.

What's the Difference Between Modeling and Forecasting?

Great question. People often use these terms interchangeably, but they are two very different—though connected—parts of the puzzle.

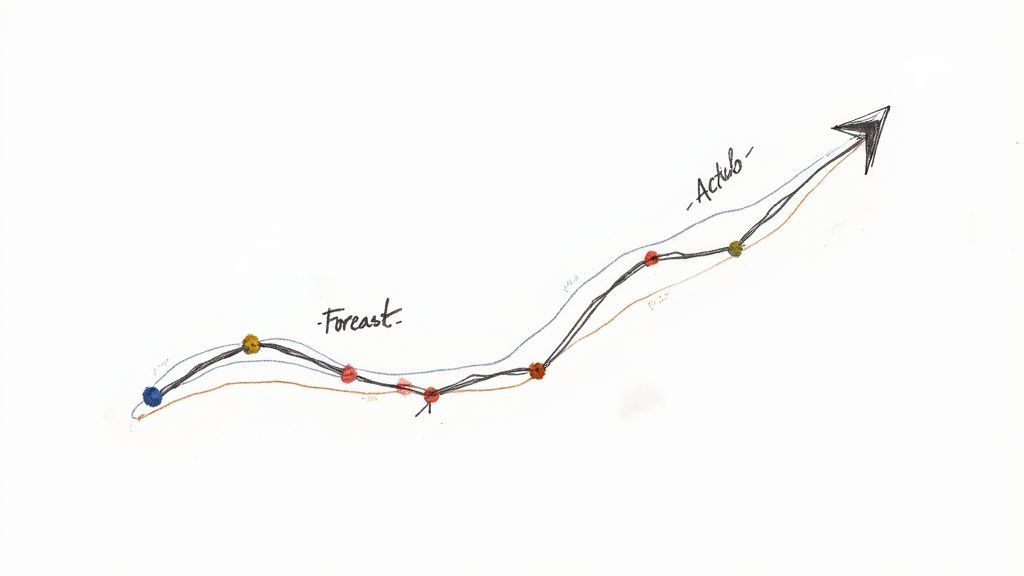

Forecasting is all about predicting what is likely to happen. It answers questions like, "How many widgets are we going to sell next quarter?" Think of it as an educated guess about future demand based on past data and trends.

Supply chain modeling, on the other hand, figures out the best way to respond to that forecast. It takes the forecast as a starting point and answers the strategic "how" questions:

- "Given that demand, what’s the cheapest way to make and ship those widgets?"

- "Which factory should produce them, and which warehouse should we stock them in?"

Put simply, forecasting gives you the destination (the demand you need to meet). Modeling draws the best map to get there—the most efficient, resilient, and profitable route possible.

Tired of manually digging through your inbox for invoices? Invowl is an AI tool that connects to your email and automatically finds, reads, and organizes every invoice for you. Reclaim hours of your time and uncover significant savings by letting our AI handle the administrative headache, so you can focus on what matters most—growing your business. Learn more at https://www.visusly.com.