If you want to seriously cut operational costs, you need to think bigger than just slashing a line item here or there. It’s about a smarter, more holistic approach that weaves together process improvements, smart automation, and modern technology. This isn't about painful budget cuts; it's about building a leaner, more profitable business from the ground up.

Your Modern Playbook for Slashing Operational Expenses

Real, sustainable cost reduction isn't about frantic, short-sighted cuts that end up hurting your growth. It’s about being strategic. The real goal is to surgically remove waste and inefficiency, not vital organs of your business.

The most effective strategies I've seen always combine a few key areas. You have to look at your daily workflows, figure out where new tech can make a real difference, and get a better handle on your supplier relationships.

A Multi-Pronged Approach to Savings

A successful cost-reduction plan almost never relies on a single magic bullet. It’s the combination of several core strategies that creates a powerful, lasting effect. The smartest companies define clear cost-reduction goals and use proven methods to systematically root out waste. For a deeper look into the frameworks, you can explore some of the strategic cost reduction methodologies from Kaizen.com.

To get started, here are a few core strategies we'll be breaking down. These are the fundamental pillars for building a more efficient operation.

| Core Strategies for Operational Cost Reduction | | :--- | :--- | :--- | | Strategy Area | Key Action | Primary Benefit | | Process Optimization | Find and fix bottlenecks in daily workflows. | Do more with the same resources, increasing output. | | Technology Adoption | Use tools like AI to automate repetitive, manual tasks. | Reduce human error, save time, and gain insights. | | Procurement Management | Actively negotiate with vendors and manage contracts. | Prevent overspending and secure better pricing. | | Cost-Conscious Culture | Empower the entire team to spot savings opportunities. | Create a company-wide habit of efficiency. |

This multi-pronged approach ensures that you're not just making one-off cuts but are fundamentally changing how your business operates for the better.

By treating cost management as an ongoing discipline rather than a one-time project, you build a foundation for continuous improvement and long-term financial health.

This guide is your high-level roadmap to these modern, actionable solutions. We’re setting the stage for a deep dive into building a more efficient and profitable business, starting with the basics of process improvement. Once you understand these core pillars, you’ll be ready to make intelligent decisions that trim expenses without sacrificing quality or your ability to grow. This is how you learn to reduce operational costs for good.

Streamline Operations with Process Optimization

Theory is great, but real savings are found in the trenches of your day-to-day operations. To get a real grip on your operational costs, you first have to understand how your business actually works. This means rolling up your sleeves and doing a thorough process audit—mapping your core workflows from start to finish.

Think of it as creating a blueprint for your business. The goal is to visually trace every single step, uncover those hidden bottlenecks, and pinpoint redundant tasks that are quietly eating away at your time and budget. You can't fix what you can't see.

Conducting a Practical Process Audit

You don't need to hire expensive consultants for this. Just pick one critical, high-volume process and dive in. If you run an e-commerce store, this might be order fulfillment. For a creative agency, it could be your client onboarding sequence.

Document every action. Who does what? What tools are they using? How long does each step really take? Getting your hands dirty with this kind of audit forces you to confront the small, accumulated slip-ups that often fly under the radar.

This is where methodologies like Lean (focused on eliminating waste) and Kaizen (focused on continuous, small improvements) really shine. That e-commerce company, for example, might discover that fulfillment mistakes are piling up simply because packers have to walk across the warehouse to print shipping labels. A simple change, like moving the printer, could slash both errors and labor hours.

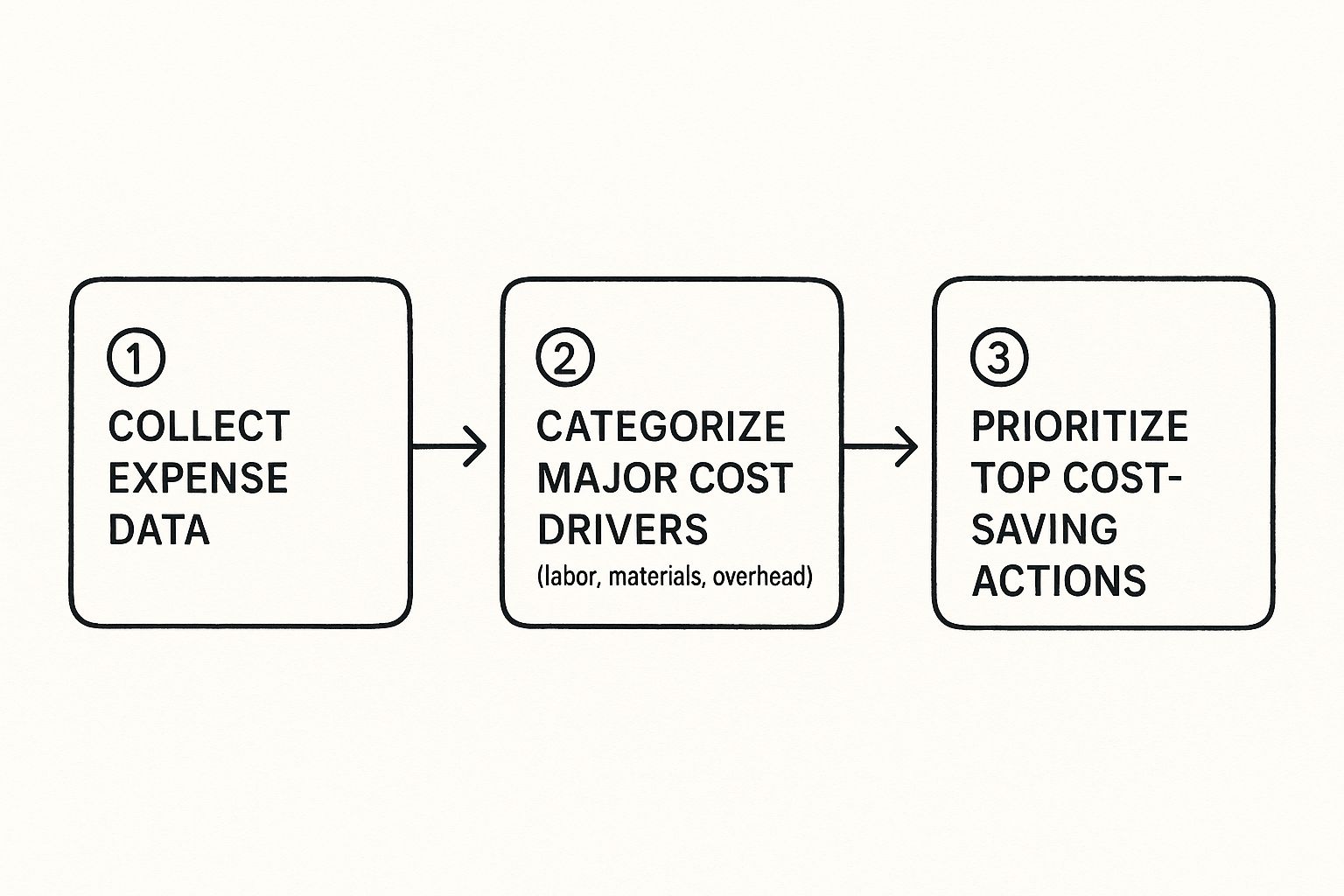

This visual shows a simple way to think about this audit process.

As you can see, after you've gathered the data and identified the real cost drivers, the most important step is prioritizing your actions to get the biggest bang for your buck.

From Mapping to Action

Once your process map is laid out, you can start asking the tough questions.

- Which tasks are repetitive and scream "human error"? These are your prime candidates for automation.

- Where do delays and handoffs create friction? Smoothing out these transitions can dramatically speed up the entire workflow.

- Are multiple people doing the exact same work? Consolidating those responsibilities can make a huge difference in efficiency.

Answering these questions almost always reveals immediate opportunities. A classic example is manually matching purchase orders to invoices. It's a textbook bottleneck—slow, tedious, and a breeding ground for payment errors.

It’s also an area where communication often breaks down, especially between you and your accountant. For a deeper dive on fixing that specific headache, check out our guide to streamline accountant collaboration and cut out the endless back-and-forth emails.

By focusing on the process instead of just the outcome, you uncover the root causes of high operational costs. A small tweak to a daily workflow often delivers more sustainable savings than a one-time budget cut ever could.

Ultimately, process optimization is about making your business leaner and more effective without a massive upfront investment. These small, targeted adjustments add up, leading to serious long-term savings and a much more resilient operation.

Use Automation and AI to Cut Costs the Smart Way

Trying to manage every business task by hand is like running on a treadmill—you're working hard but not really getting anywhere. The good news is that technology, especially automation and AI, offers one of the most effective ways to stop spinning your wheels and start making real progress in reducing operational costs.

This isn't about replacing your team. It's about empowering them.

When you automate repetitive, low-value work, you free up your people to focus on the strategic initiatives that actually grow the business. That shift is absolutely essential for building a more efficient, resilient operation.

Think about it. Robotic Process Automation (RPA) can handle tedious data entry, and customer service chatbots can answer routine questions 24/7. This cuts down on support costs while making your response times faster. The impact is huge. In fact, some reports show that adopting AI and automation can slash operational costs by as much as 30%. You can dig into more of these cost-saving technology applications over at cmcglobal.com.vn.

Pinpoint Where Automation Can Make the Biggest Impact

If you're wondering where to start, look no further than your financial operations. This area is almost always drowning in manual tasks.

Just consider your accounts payable process. How many hours does your team pour into manually typing in invoice data, matching it against purchase orders, and then chasing down approvals? Every single step is a potential breaking point, leading to costly errors, late payment fees, and even strained relationships with your vendors.

This is where AI-powered tools completely change the game. A modern invoice management platform can automatically:

- Pull data from any invoice format, killing manual entry for good.

- Check details against your existing records to catch mistakes.

- Send invoices directly to the right person for a quick approval.

By getting these financial workflows on autopilot, you're not just saving a few hours. You're building a more accurate, reliable, and cost-effective foundation for your entire business.

From Manual Grind to Strategic Advantage

A perfect example of this in action is AI-driven invoice management. Platforms like Invowl plug right into your email, automatically finding and processing every single invoice without you having to lift a finger.

The image below gives you a glimpse of how a clean, central dashboard gives you an instant overview of your spending. It makes spotting trends and finding potential savings almost effortless.

This kind of visibility transforms a boring administrative chore into a real strategic advantage. You can finally see exactly where your money is going, giving you the upper hand when negotiating better terms with suppliers. It fundamentally flips financial management from a reactive headache to a proactive win.

Automate Your Invoice Workflow for Maximum Savings

Putting your invoice process on autopilot does more than just cut down on clerical work—it directly protects your bottom line.

Manual data entry is a notorious source of mistakes, from simple typos to paying the same bill twice. These little errors can easily add up to thousands of dollars in losses over a year. An automated system simply prevents them from happening in the first place.

By ensuring every bill is processed accurately and on time, you can wave goodbye to late fees and start taking advantage of early payment discounts from vendors. This one-two punch of error prevention and timely payments creates a powerful, recurring source of savings. To see what's possible, you can learn more about how to automate invoice management in our detailed guide. The hours and dollars you get back can be put right back into activities that drive real growth.

Master Your Procurement and Vendor Negotiations

Your suppliers are more than just line items on an expense report—they’re strategic partners. Treating them that way is a powerful, yet surprisingly overlooked, way to cut your operational costs.

Effective procurement isn't about squeezing every last penny out of a vendor. It's about building strong, transparent relationships that create value for both of you.

First things first, get a clear picture of your spending. Are you buying similar things from five different suppliers? That's a huge red flag. Consolidating your purchases with fewer, high-quality vendors can unlock significant volume discounts and give you much more leverage to negotiate better payment terms. A single, larger contract is always more attractive than a handful of small ones.

This simple shift turns procurement from a reactive task into a proactive savings engine. In fact, research shows that companies using strategic category management can slash costs by 10-15% just by consolidating their spending and building stronger supplier partnerships. You can dig deeper into how AI is boosting procurement cost reduction at concord.app.

Forge Smarter, More Flexible Contracts

Your contracts are your rulebook, so make sure they’re actually written to benefit you. When you're at the negotiating table, don't get fixated on the initial price. The real savings often come from building in clauses that protect you down the line and ensure you're getting the value you paid for.

Here are a few non-negotiable clauses I always try to include:

- Performance Reviews: Schedule regular check-ins (quarterly is a good starting point) to review service levels and quality. This keeps vendors accountable and gives you a formal opportunity to make adjustments if things aren't working out.

- Price Adjustment Terms: Clearly define the conditions under which prices can change. This prevents those "surprise" hikes and locks in a predictable cost structure for your budget.

- Early Termination Options: If a vendor consistently underperforms, you need a clean, low-cost way to exit the agreement without getting hit with massive penalties. Don't get trapped in a bad relationship.

These small additions give you control and flexibility. They turn a static document into a dynamic management tool that helps you stay on top of your expenses.

Use Technology to Never Miss a Detail

Let's be honest: manually tracking dozens of contracts is a recipe for disaster. Important dates, like sneaky auto-renewal deadlines, can easily slip through the cracks, locking you into another year of an overpriced or unnecessary service. I've seen it happen countless times.

This is where modern tools can be a game-changer.

AI-powered contract management software acts as your digital watchdog. It automatically scans your agreements, flags key dates, and alerts you about potential compliance issues or upcoming renewals.

This gives you plenty of time to decide whether to renegotiate, shop around for a better deal, or simply terminate the contract. Instead of being blindsided by a surprise invoice, you’re in the driver's seat, making informed decisions that directly impact your bottom line.

By preventing these unforced errors, you can turn your vendor management process from a source of anxiety into a consistent source of savings.

Cultivate a Cost-Conscious Company Culture

Here’s a hard truth: lasting cost reduction is a team sport. It can't just be a top-down mandate from the C-suite. The strategies that truly stick are the ones that get woven into the very fabric of your company culture.

When every single employee feels empowered to spot waste and suggest improvements, you kickstart a powerful, self-sustaining cycle of efficiency. But this doesn't happen by accident.

It all starts with transparency. If your team doesn’t understand the “why” behind cost management, they’ll just see it as management being cheap. Share the high-level financial goals. Explain how operational efficiency helps secure the company's future—and everyone's role in it. When people feel like they’re part of the solution, their mindset shifts from passive observer to active problem-solver.

Empower Your Team to Drive Savings

Some of the best cost-cutting ideas don't come from a spreadsheet. They come from the people on the front lines who deal with clunky, inefficient processes every single day. Your job is to build a system that captures, evaluates, and rewards their insights.

A simple way to do this is by launching an employee suggestion program. And no, I don't mean a dusty suggestion box in the breakroom. This needs to be a real, formal system where people can submit ideas that lead to documented savings.

For this to actually work, you have to do two things:

- Offer Real Incentives: Don't be stingy. Reward successful ideas with a small percentage of the first year's savings, a cash bonus, or public recognition. This shows you’re serious about valuing their input.

- Provide Feedback on Every Idea: This is crucial. Even if an idea isn’t feasible right now, take the time to explain why. It shows that every suggestion is heard and respected, which encourages people to keep trying.

The goal is to make every employee a guardian of the company's resources. When people feel a genuine sense of ownership, they naturally start looking for ways to work smarter and eliminate waste. That's how you build a culture of continuous improvement.

Train for Success and Ensure Adoption

Rolling out new, more efficient processes or tech is only half the battle. If your team isn't trained properly or doesn’t see the point, adoption will flop. You’ll be left with an expensive tool nobody uses and the same old inefficient habits.

Frame new technology not as a threat, but as a tool to make their jobs less tedious. For example, when you introduce an automated invoice system, show them exactly how it kills hours of mind-numbing data entry, freeing them up for more interesting, high-value work.

By focusing on the "what's in it for me" and providing real, hands-on support, you ensure new systems are actually embraced and deliver the cost savings you were promised. For more tips on smoothing out your financial operations, check out the articles on the Invowl blog.

Frequently Asked Questions

When you start digging into cost reduction, a lot of questions pop up. We get it. Here are some of the most common ones we hear, with straight-to-the-point answers to help you get moving.

Where Do I Even Start with Reducing Operational Costs?

The absolute first move is a full-on audit of your current spending and your daily processes. You can’t fix what you can't see. Trying to cut costs without a clear map of where your money and time go is just guesswork.

Start by pulling all your operational spending from the last 6 to 12 months. Group everything into categories. While you do that, also map out one of your core business workflows—like how you handle a new customer order from start to finish. This two-pronged attack will instantly spotlight both the money pits and the process logjams, giving you a solid, data-backed starting point.

How Can a Small Business Possibly Afford AI and Automation Tools?

This is a huge misconception. Many of today's best AI and automation tools are surprisingly affordable, especially when you weigh them against the cost of manual work. The trick is to look for Software-as-a-Service (SaaS) platforms that offer flexible pricing, like monthly subscriptions or pay-as-you-go models.

For example, an AI-powered invoice tool or a basic CRM with automation can cost less per month than what you'd pay a person for just a few hours of tedious data entry.

Pro Tip: Don't try to boil the ocean. Pick one high-impact, high-frustration area to start with. Automating your invoice processing or using a simple chatbot for common customer questions are fantastic first steps. The time you save and the errors you prevent often pay for the subscription in just a few months, making it a no-brainer investment even for the leanest operations.

This targeted approach proves the tech's value before you go all-in, so you know exactly how it's contributing to your bottom line.

Will Cutting Costs Hurt Our Product Quality or Customer Service?

This is the big fear, right? But the answer is a firm no—if you do it smartly. Real cost reduction isn’t about blindly slashing budgets or buying cheaper materials. It’s about rooting out waste and inefficiency. It's about working smarter, not cheaper, which almost always leads to better quality and service.

Think about it:

- Automating boring, repetitive tasks frees up your talented people to handle complex customer problems, which instantly boosts the quality of your support.

- Fine-tuning your production process naturally cuts down on mistakes, which means a more consistent, higher-quality product for your customers.

The key is to focus on intelligent spending and process improvements, not just hacking away at your budget. Before you make any change, always ask: "How does this affect the customer?" If the answer is "negatively," then it's not a strategic saving—it's a future problem.

How Do I Get My Team on Board with Cost-Cutting?

Getting your team's buy-in isn't optional; it's essential. Without it, any changes you make will eventually fail. Your best tools here are transparency and inclusion. You have to frame this as a team effort to build a healthier, more resilient company, not just a top-down order to spend less.

Start by clearly explaining the why behind the changes. When people understand the big picture—that this is about long-term stability and growth—they're much more likely to support it.

Better yet, get your team leaders involved in finding the waste in their own departments. They know where the friction is. And most importantly, create a simple incentive program that rewards employees for ideas that lead to real, documented savings. When your team feels like they are part of the solution and can see how efficiency benefits everyone (including them), they'll become your biggest champions for change.

Ready to stop wasting hours on manual invoice work and start uncovering hidden savings? Invowl connects to your inbox, extracts all your invoice data automatically, and gives you the insights you need to reduce operational costs. Try it today and see how much you can save.